Grade 10.9 Thin Hexagon Nut

Parameters

Standard: GB/T 54-1976

Material: Carbon Steel

Product Grade: Grade A Grade B Grade C

Applicable Scenarios: Communications Power Construction New Energy Petrochemical Light Industry Precision Machinery Electronic Equipment Medical Devices Aerospace Auxiliary Components Rail Transit Automotive Industry General Equipment Engineering Machinery Agricultural Machinery Mechanical Industry Solar Power Generation

Strength Grade: 10.9

*The picture only shows the product shape; please refer to the actual product for details.

Size(mm): M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30

Width Across Flats (mm): 10 14 17 19 22 24 27 30 34 36 40 45

| Global Certifications |

|

| Main Materials |

|

| Surface Treatment |

|

| Product Range (Fasteners) |

|

| Main Production Equipment |

|

| Testing Equipment |

|

| Packaging Solutions |

|

| Technical Services |

|

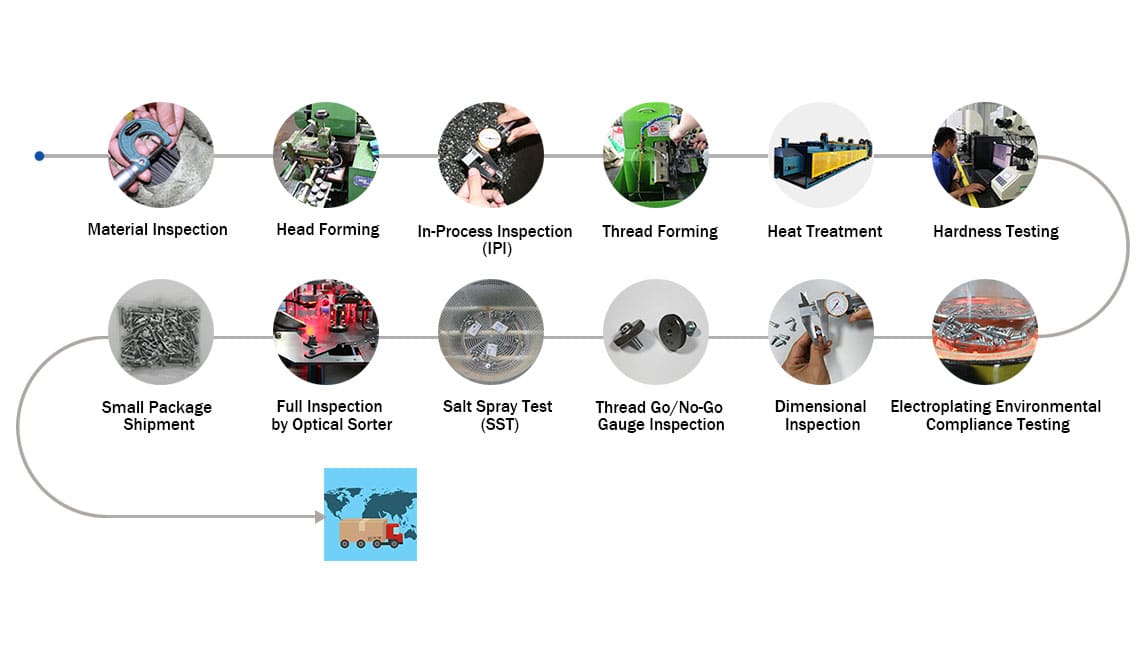

Production Process · Precision in Every Step

BOSHI- Fasteners Manufacturer and Supplier

Harriet

Manager

- Tel: 85366138126

- Whatsapp: +85366138126

- Email: boshifastener@gmail.com

WhatsApp

Our Address

Xintang Town, Zengcheng District, Guangzhou City, Guangdong Province, China