Magnetic Engine Oil Drain Plug

Parameters

*The picture only shows the product shape; please refer to the actual product for details.

I. Product Introduction

Though seemingly small and compact, the oil drain bolt for automobile engines is an indispensable key component in the maintenance of car engines. It undertakes the vital mission of draining waste engine oil accurately and safely, safeguarding the smooth operation and long-term maintenance of the engine. This exquisitely crafted oil drain bolt for automobile engines has become a trusted premium choice for numerous automotive maintenance professionals and car owners by virtue of its outstanding quality and excellent performance.

II. Core Advantages

(1) High-Quality Material Selection, Sturdy and Durable

High-Strength Alloy Material

We adopt high-strength alloy steel specially developed for the harsh working conditions of automobile engines. Undergoing multiple rigorous forging and heat treatment processes, it boasts extremely high strength and toughness. This material can withstand various complex stresses generated during engine operation and the torque force from frequent oil draining operations, ensuring no deformation, fracture or other issues occur during long-term use, and providing stable and reliable support for engine oil draining work.

Selected Sealing Material

It is matched with a high-performance fluororubber sealing gasket. Fluororubber is renowned for its excellent oil resistance, high temperature resistance (able to withstand high-temperature environments up to [specific temperature]℃), chemical corrosion resistance and superior elasticity. When the engine is in operation, facing long-term immersion in high-temperature engine oil and pressure changes under different working conditions, it can closely fit the oil drain hole, effectively preventing engine oil leakage, keeping your engine in good sealing condition at all times, and avoiding engine failures and environmental pollution caused by oil seepage.

(2) Precision Manufacturing, Perfect Compatibility

High-Precision Thread Processing

Utilizing advanced CNC machining technology, we conduct fine grinding and precise processing on the threads of the oil drain bolt, controlling the pitch error within an extremely small range. The thread surface is as smooth as a mirror, ensuring a perfect match and tight engagement with the threads of the oil drain hole on the automobile engine oil pan. During installation, it can be smoothly screwed into place with a gentle twist, which not only enables convenient and fast operation, but also effectively avoids thread slipping, loosening and other problems caused by poor thread fit, guaranteeing the safety and stability of the oil draining process.

Strict Size Control

We are fully aware of the extremely high precision requirements for all components of automobile engines. Therefore, the size design of the oil drain bolt strictly complies with the standards and specifications of the automotive industry. Every detail, from the length and diameter of the bolt to the size of the head, has undergone accurate measurement and repeated verification. It ensures seamless compatibility with most mainstream automobile engine models on the market with strong universality, saving you the trouble of finding a suitable oil drain bolt.

(3) Humanized Design, Easy Operation

Easy-Dismantling Head Design

The bolt head features a hexagonal design that conforms to ergonomic principles, facilitating disassembly and installation with conventional socket wrenches. It can be easily handled both in professional auto repair shops and during self-maintenance by car owners, saving operation time and improving maintenance efficiency. Meanwhile, the surface of the head has undergone special anti-slip treatment, allowing you to firmly hold the wrench even when your hands are stained with oil, preventing slipping and ensuring precise operation.

Clear Marking Design

Key information such as product specifications and torque parameters is clearly marked on the bolt shank, enabling maintenance personnel to quickly confirm during operation, avoiding improper installation caused by misoperation, and making the use of the oil drain bolt more scientific and standardized.

(4) Multiple Protections, Long-Lasting Durability

Anti-Corrosion Coating Treatment

To adapt to the complex operating environment in the automobile engine compartment, the surface of the oil drain bolt has undergone an advanced anti-corrosion coating process, forming a dense protective film. It effectively isolates air, moisture and other corrosive substances, greatly enhancing the corrosion resistance of the oil drain bolt. Even when exposed to harsh environments for a long time, it can still maintain a bright and new appearance and intact internal structure, extending the service life of the product and saving your replacement costs.

Anti-Wear Design

For the key parts where the oil drain bolt contacts the sealing gasket and where the threads experience frequent friction, we adopt a special strengthening treatment process to increase the hardness and wear resistance of these parts. It ensures no excessive wear occurs during multiple disassembly and installation processes, maintaining excellent performance at all times and guaranteeing the reliable use of the oil drain bolt.

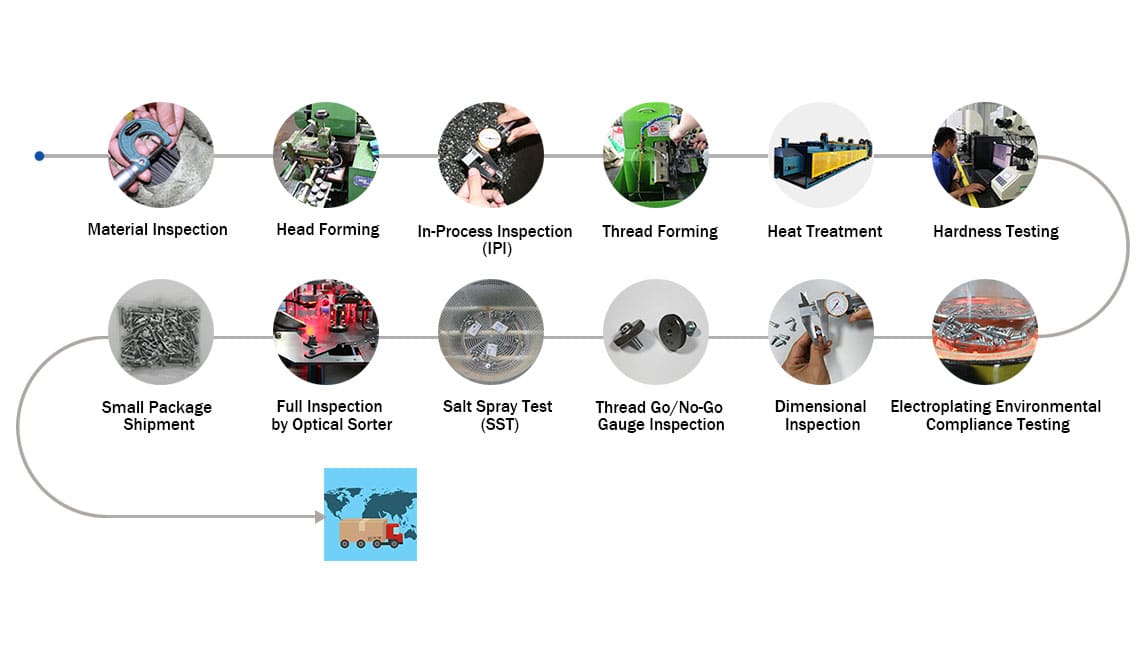

Production Process · Precision in Every Step

BOSHI- Fasteners Manufacturer and Supplier

Harriet

Manager

- Tel: 85366138126

- Whatsapp: +85366138126

- Email: boshifastener@gmail.com

WhatsApp

Our Address

Xintang Town, Zengcheng District, Guangzhou City, Guangdong Province, China